Manufacturing facilities have unique security needs. Facility managers are responsible for protecting everything from people, property, equipment, and products to data, records, and other sensitive information. And while it's necessary to abide by an array of regional, federal, and industry standards and laws, all of this security and compliance needs to be balanced with allowing workers, contractors, inspectors, and customers to use these worksites safely and efficiently. That's why a visitor management system (VMS) may be a useful tool in managing manufacturing facilities.

Visitor management systems can help address both physical security and cybersecurity needs. And the best systems can integrate with the tools already in place in a manufacturing facility.

Below, we'll look at some of the ways the manufacturing industry can use a VMS.

Manufacturing facilities play an integral role in the supply chain, affecting nearly every product and service in the consumer ecosystem. Any process disruptions can have significant ripple effects throughout the industry or the economy. As a result, protecting manufacturing sites is a complex and multi-faceted endeavor.

To secure a manufacturing site, facilities managers need to perform regular risk assessments and consistently employ the most up-to-date physical and cybersecurity measures. Risk assessments need to take into account factors such as:

According to a 2019 CISA report, the manufacturing sector reported the highest number of insider attacks in the critical infrastructure sector. IBM's most recent Insider Threat Report from 2020 estimated that the average cost of insider attacks - which can come from employees, contractors, suppliers, and other third-party vendors - cost over $11 million in 2020, and the number of incidents increased by 47% from the previous year.

Even when personnel resources are allocated to physical security and cybersecurity and from both insiders and outside bad actors, manufacturing facilities increasingly need to invest in risk mitigation tools, such as surveillance, access control, identity authentication tools, and visitor management systems and software. Being proactive allows manufacturing facility managers to not only predict, prevent, and prepare for threats, but also deter, detect, mitigate, and report them.

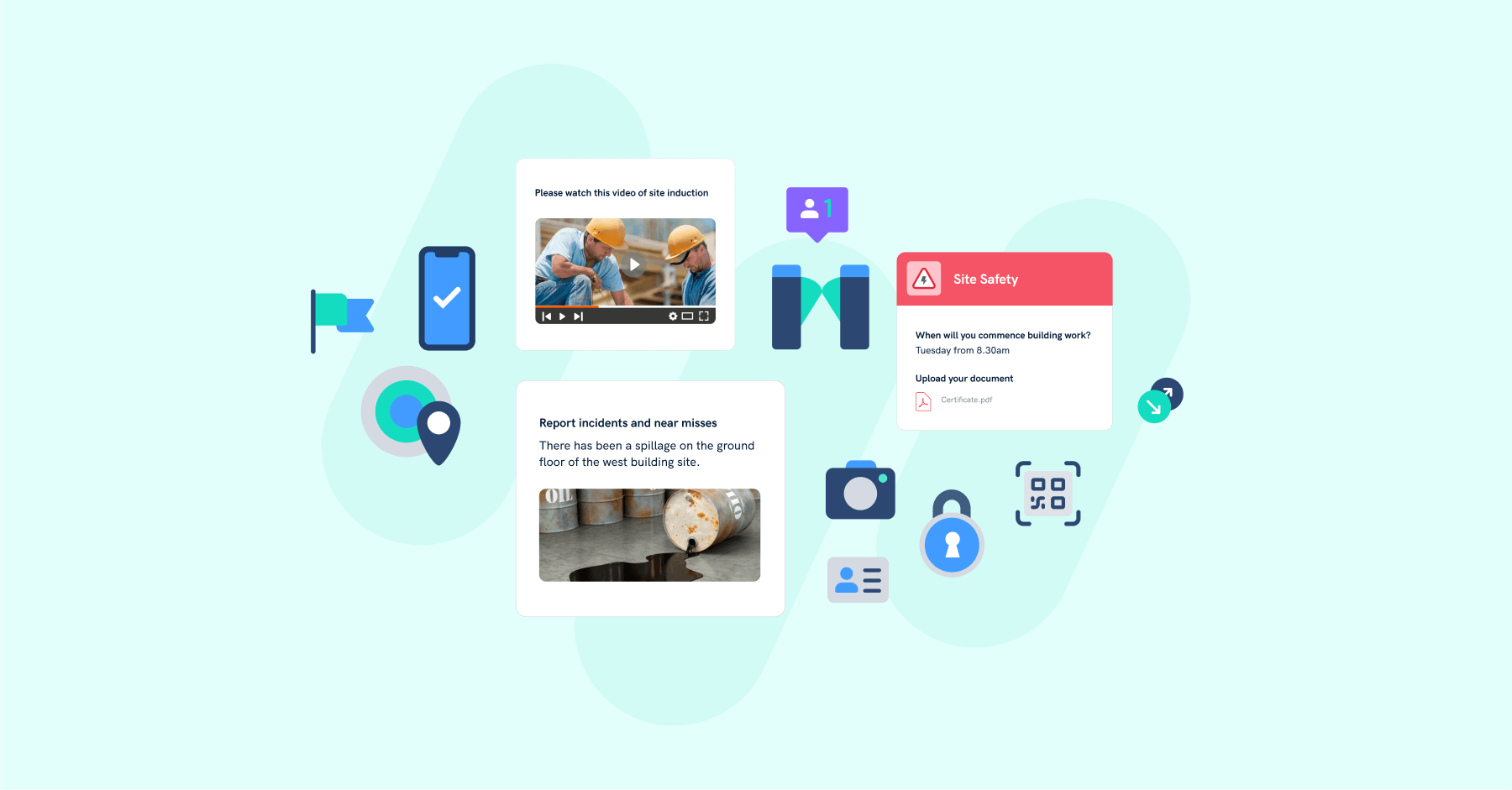

From the moment guests walk through the door of your manufacturing facility, a VMS helps greet and guide them, making a good first impression and boosting your brand image. VMS technology from Sine also follows your guests on their journey throughout your facility, helping them understand the risks and stay out of danger. By the time they leave, people visiting your site may have assisted you to assess future risks, make decisions about how to manage new visitors, and add insight into how people use a manufacturing worksite.

Here are just some of the major benefits a VMS like Sine can help you manage a manufacturing facility:

A digital visitor management system provides a variety of safety features for everyone at a manufacturing facility. For example:

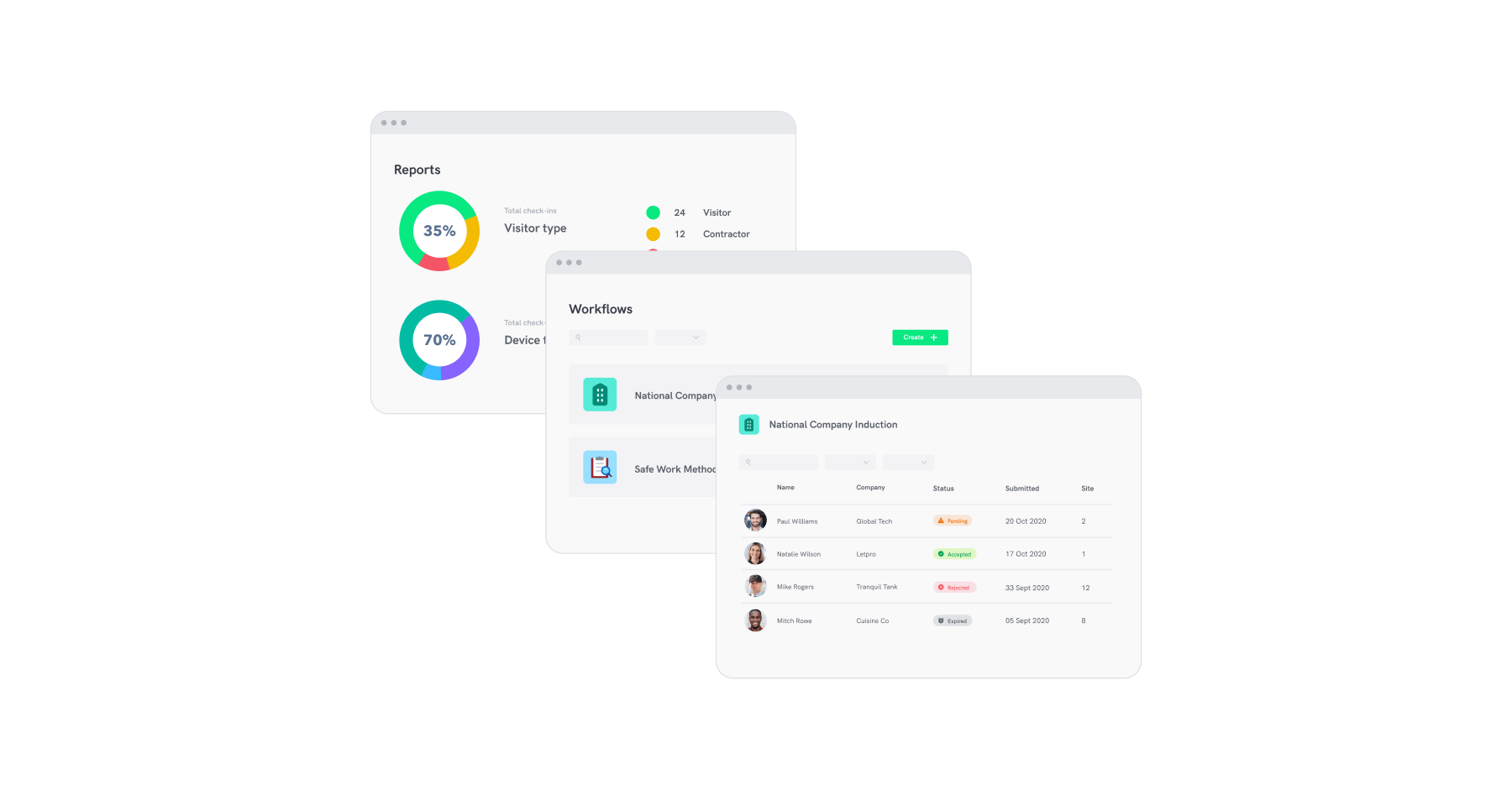

While vetting your visitors before their entry is a great start when it comes to improving security, manufacturing facilities with sensitive information, special tools, or dangerous equipment may also need a real-time view of what's happening on site. Tools that record visitor information can even help boost your employees' productivity by preventing them from being distracted by surprise visitors.

Visitor management tools and integrations that help provide facilities managers in manufacturing the visibility they need include:

Collecting visitor data allows for unique insights, but it is an increasingly tricky business in light of new privacy regulations. The manufacturing industry has seen a steep incline in data breaches over the last few years. In 2021, Verizon reported that 66% involved the theft of personal information. That's why Visitor Management features may balance information collection with data protection, and compliance.

While manufacturing companies are at increasing risk of security breaches and acts from vandalism to theft can cost time and money, most people who try to enter a manufacturing facility are employees, contractors, and inspectors who have busy schedules and require an efficient check-in or entrance process. That's why investing in Sine's solutions is also an investment in convenience.

It's crucial for a visitor management system to streamline the visitor check-in process while increasing security and improving the protection of visitor data.

When it comes to managing contractors, all of these issues come up and show just how Sine can assist the manufacturing industry. All corners of the industry rely on contractors for their specialized skills, but also have to be careful when it comes to the risks they may pose to employees, for example, when they're not familiar with facility protocols.

Sine's VMS and its integrations can be useful in managing contractors at a manufacturing facility, including: